What is Flux in Soldering?

March 17, 2023

Soldering is a process often used in electronics, metalworking, and other manufacturing processes. To achieve proper soldering results, flux in soldering must be used — but what is it, and how does it work?

If you are new to soldering, learning about flux and understanding how it works helps! This article seeks to provide an explanation of flux and its role in soldering. Plus, the types of flux available for different soldering tasks.

Flux in Soldering

Solder is a metal alloy often made of tin and lead. To melt solder, a soldering iron is a must. The soldering process does the job of joining different types of metals together. However, there are times when a solder tends to be not solid enough to bond components. This is where flux in soldering comes into play.

You may be wondering, “why is flux necessary?” when a soldering iron alone can supply the heat to melt the solder and bind the joints together.

Solder flux is a chemical agent used before and during the soldering process. Using it is incredibly important to achieve the best results possible.

Flux helps lower the surface tension of the metals being joined. At the same time, it prevents oxidation from forming on any of the metal’s surfaces. This makes it easier to get a stronger joint and eliminates corrosion during the process.

Additionally, flux helps improve wetting between the two surfaces. This provides electrical contact and enhances the strength of solder joints.

Overall, flux in soldering accomplishes three things:

- Reduces oxidation

- Improves electrical contact

- Alters the surface tension of the molten solder

You can be sure your projects will turn out perfectly every time!

Different Types of Flux

There are various types of flux available for different soldering operations and materials. It is important to be aware of these varieties and what uses each is best suited for.

Organic

Organic acid fluxes are low-cost and have similar effectiveness for a range of metals. This type of flux uses organic acids as activators. It cleans surfaces by removing oxide layers and leaves behind residue for anti-corrosion.

Best used for tin-to-tin, aluminium-to-aluminium, copper-to-copper, and also brass-to-brass solder joints on electronic components.

Inorganic

Inorganic acid fluxes offer superior activity over their organic counterparts. They contain activators like ammonium chloride, which have higher melting temperatures. This type of flux can also be used on heavily oxidised surfaces, e.g. copper or brass.

The residues formed from these inorganic compounds need post-cleaning with solvents, though. Residues left behind could compromise the connection’s integrity.

Rosin

Rosin is one of the most common grades of soldering flux. It consists of rosin as an activator and stabiliser, along with natural resin.

Rosin core fluxes do not contain any corrosive elements, nor does it leave any residue. This means they do not need to be cleaned off after use. Moreover, this type of flux has a low melting temperature. Thus, it is best suited for consumer electronics applications, such as:

- connecting wires

- mobile phone motherboard repairs

When cleaning is necessary, use specific chemical solvents that involve fluorocarbons.

No-clean

No-clean solder flux contains no corrosive contents. Plus, there is no need to clean any residue. This leaves no chance of contamination or weakening of joint integrity.

Its wide welding scope allows it to solder all kinds of surface finish levels. Its active cleaning ability also makes up for its lacking adhesion capabilities. This ensures that stable joints are attained quickly without any hassle.

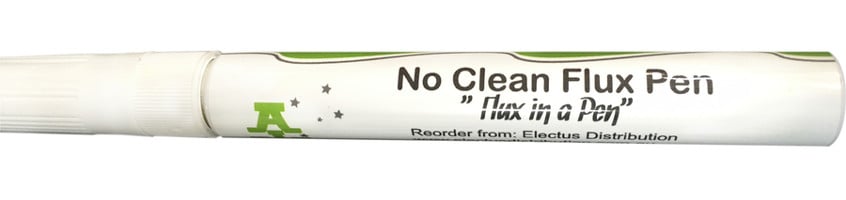

Solder Flux Pen – No Clean 12ml with Chisel Tip

Product code: JNS3036

Quick-drying and ideal for use when replacing surface mount components. When applied to solder joints, it will aid reflow while heating to remove the component. Also, you can apply it to bare copper or tinned tracks to provide excellent solderability.

For those fluxes that are more corrosive, cleaning is crucial. Experts recommend opting for rosin-based flux agents for electrical soldering. Also, avoid corrosive agents as most electronics and wires are extremely fragile.

Have a look at this rosin-based solder flux below:

Solder Flux Paste – Rosin, 56g Tub

Product code: JNS3070

A low-residue rosin solder flux paste, perfect for improving your soldering joints. The active ingredients are non-ionic and non-conductive, including when moisture is present.

How to use: Turn off and unplug the device or equipment. Clean the surface, then apply flux. Heat and melt flux, then apply solder. Clean and wipe off the residue. Wash hands after use.

The Applications

Although there is a variety of flux in soldering available, all are not applicable to just one method. These different soldering methods include:

- Selective soldering. The soldering flux used in this method is towards fluid composition. To solder, the flux is sprayed over the surface. The drop jet process is another great approach, giving a more precise outcome.

- Solder reflow. For this composition, there is a sticky flux mixed with small beads of metal solder. The paste holds the parts to be soldered in place until the heat causes it to reflow. While the metal surface is being cleaned, the paste also seals any air gaps to prevent oxidation.

- Wave soldering. The flux is sprayed on the board before soldering, containing more solvents. If the board is soldered using a less corrosive flux, it needs extra cleaning.

Soldering Electronics with Flux Tips

- Apply a good amount of flux upon the board beforehand.

- Go for dense composition over liquid in manual soldering.

- Avoid no-clean soldering flux as solvents, as it cannot remove these.

- Prevent using solvent and water for flux cleaning. But if necessary, use any fresh solvent to remove the remaining flux.

- Prepare de-ionised water beforehand to clean the rest.

- Wear safety equipment to prevent any accidents.

Flux in Soldering: The Bottom Line

Flux in soldering is a critical component. Its main role is to remove oxidation when heating the surface together. But it also plays a vital part in ensuring the solder forms a strong bond with the items being connected.

This article was originally published in December 2020 and has been updated.

© Wiltronics Research Pty Ltd 2023

Write a Comment

You must be logged in to post a comment.