What Is Borosilicate Glass and Why Is It a Great Investment?

February 1, 2021

You may or may not have heard but glass is not created equally. And although the variations may look similar, they’re not the same.

To understand the different forms and properties of glass, let us first understand what is a glass and how it’s made.

Glass is a hard material that is formed through a mixture of dry solid materials by heating. Thanks to their strength and versatility, they have nearly limitless uses, such as:

- In construction, providing facing for most modern buildings, including architectural glass feature for structures;

- Diverse uses in the home, from television screens, cookware to light bulbs;

- Biological, chemical and medical laboratories, e.g. beakers, test tubes, and microscopes;

- Eyeglasses and glass lenses;

- And other decorative glass objects.

Highly valued for its optical properties, glass also can reflect, bend, transmit, and absorb light with accuracy. But then again, not every type of glass is made in the same manner.

From high silica to lead, glass comes in different forms and is divided into types based on chemical composition. One of the common types is Borosilicate glass.

Borosilicate Glass: How It Is Made

The process of creating borosilicate glass demands higher temperatures compared to standard types like soda-lime glass. Since it uses more energy, it’s more difficult to manufacture, making it more expensive.

But because this type of glass offers durability and heat resistance to chemical changes, it’s used for kitchen and laboratory applications, as well as industrial settings—everything from cookware and bakeware to test tubes, beakers, graduated cylinders and more.

Uses of Borosilicate Glass

- Cookware. Did you know that Pyrex is known for its use of borosilicate glass in cookware? Borosilicate glass doesn’t crack at high temperatures – even in ovens. This makes it an ideal choice for casserole dishes.

- Research and Chemistry Laboratories. Borosilicate glass will not crack or break down when used in mixing any kind of compounds that can be found in the lab. It’s proven to be resistant in both extremes of acid and heat. No wonder why chemists, including researchers, love this type of glass.

- Industrial Applications. Many industrial manufacturers favour borosilicate glass rather than the traditional soda-lime glass when it comes to producing a variety of heavy-duty applications, such as panels on consoles or viewing machinery.

- Water Bottles and Wine Glasses. Some water bottles and wine glasses are made out of borosilicate glass as well. Manufacturers make them in this way to enhance strength and durability.

The Difference of Borosilicate Glass Between Soda-Lime and Lead

Soda-lime glass or window glass is the most common and least expensive type of glass, containing about 70% silica with soda, lime, and small amounts of other compounds. As the name suggests, it’s commonly used in windows and household glass containers.

Lead glass, also called lead-oxide glass or lead crystal, is a softer version of glass that contains at least 20% lead oxide. This makes it easier to cut into designs, but it can’t withstand high temperatures.

Since lead glass is refractive and more expensive than soda-lime glass, this type of glass is commonly used for decorative glass dishware.

Meanwhile borosilicate glass, whose main components are silica and boron trioxide, is composed of at least 5% boric oxide. Other than being durable and very heat resistant, this glass also faces far less material stress than regular glass.

Thanks to its lower thermal expansion coefficient, this adds remarkable performance at high temperatures. Moreover, it can withstand accidents that would break other glassware. Even when it does crack, it can still perform better as it rarely shatters.

Coefficient of Expansion

Tested-compatible or Coefficient of Expansion (COE) is a measurement of the rate that glass will expand and contract when it’s heated and cooled. Fusible glass manufacturers test their glass to guarantee the COE; to avoid any stress-cracks and breakage, it’s crucial to use glass that has the same COE.

As for the borosilicate glass, it has lower COE and has less material stress than the regular ones. The lower COE is, the more exceptional the glass can perform at high temperatures.

This means that a glass made out of borosilicate will not crack under extreme temperature changes, making it thermal shock resistant. In terms of the temperature, its maximum thermal shock range is 170°C, (340°F).

You can put these in the freezer then straight to the oven rack without cracking. You also can pour boiling hot water into it for some coffee without worrying about shattering the glass.

Benefits of Investing in Borosilicate Glass

Overall, it’s better for the environment. Unlike plastic water bottles which are deemed to be harmful and bad for the environment, borosilicate glass is made from natural materials that are more easily acquired than oil, which makes the environmental impact smaller. If handled with care, this glass can be used for a long time.

It’s great for you and for everyday use. Borosilicate glass resists chemical and acid degradation, so you don’t need to worry about stuff seeping into your water. You can store it in the dishwasher or even put it in the microwave.

Plus, it’s always safe to drink from. Compared to plastic water bottles or less expensive stainless steel alternatives, heating up a borosilicate glass won’t release harmful toxins into the liquid you are drinking.

Wiltronics Borosilicate Laboratory Hardware

Glass Beaker

Borosilicate glass handles thermal stress better than other common types of glass.

If you’re after premium quality laboratory glass beakers, we have GG17 Clear Borosilicate Glass Beakers (LG1101).

Thanks to its very low coefficient of thermal expansion, this beaker collection is resistant to thermal shock. In addition to being fully autoclavable, they also feature graduations to assist with measuring.

Available in sizes ranging from 25ml to 5000ml.

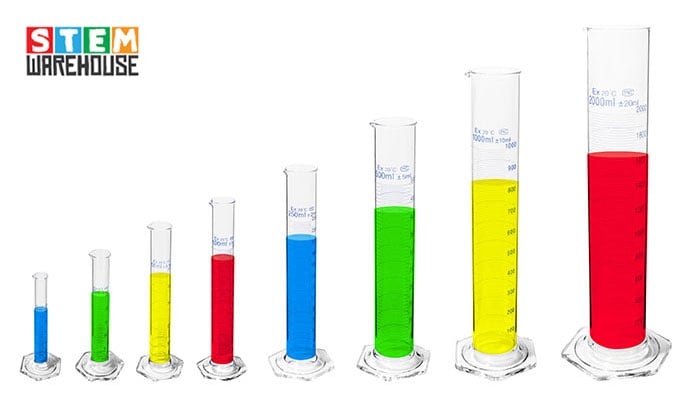

Measuring Cylinders Borosilicate Glass

Borosilicate glass measuring cylinder with a stable hexagonal base. Available in a variety of sizes (±0.5ml) with 0.5ml graduations.

- 10ml Measuring Cylinder (LG1601H-10)

- 25ml Measuring Cylinder (LG1601H-25)

- 50ml Measuring Cylinder (LG1601H-50)

- 100ml Measuring Cylinder (LG1601H-100)

- 250ml Measuring Cylinder (LG1601H-250)

- 500ml Measuring Cylinder (LG1601H-500)

- 1000ml Measuring Cylinder (LG1601H-1LTR)

- 2000ml Measuring Cylinder (LG1601H-2LTR)

Test Tubes Glass Borosilicate

We also offer test tubes rimmed with 1mm wall thickness, available in several lengths and stopper sizes. Due to their borosilicate material, they are quite robust, with thermal shock & chemical resistance.

You can check them out our borosilicate test tubes here. You also might want to check and shop our large variety of flasks, available in various sizes, styles and materials.

© Electrotech Brands Pty Ltd 2021

Write a Comment

You must be logged in to post a comment.