What Are Desoldering Stations and Their Uses: A Guide

July 15, 2022

Thinking of investing in desoldering stations soon?

Desoldering is an important skill to learn once you have gotten the hang of soldering. It is the reverse process of soldering — removing soldered joints, hence the name.

For this purpose, many electronics technicians use desoldering stations. Other special tools and techniques to desolder the object are available.

But a desoldering station is a common option for component removal from a circuit board. This equipment’s basics are very simple, but it is always best to have a handy guide like this!

Here, we will define what desoldering stations are, how they work and their uses. A brief ‘hot air rework stations vs desoldering stations’ section is also included.

Desoldering Method

Before we get straight into the tool, it is important to be familiar with the method first. Desoldering is the act of removing solder from components.

A technique used to either make corrections with a better solder job or release the joints. The basic process is straightforward, particularly when dealing with small mends.

Heat up the solder, then figure out how to get the component or wires out nicely. Next, clean up all the solder still attached to the board and/or the component.

To learn more about desoldering, in general, this desoldering guide will come in handy.

What Are Desoldering Stations?

Desoldering stations are a key element in completing a DIY electronics workstation. They have the edge over standard soldering and desoldering tools.

For one, they are more capable of handling various complex tasks. These stations also work well for multiple pass-through components.

They work by heating the solder and vacuuming to get the job done.

With one, you can carefully remove the solder from complicated and crucial boards. And you do not have to worry about hurting the circuitry.

Desoldering stations are efficient and have a range of applications. Most importantly, they meet the requirements of complex electronics manufacturing.

They come with a wide range of accessories as well. Added accessories include sharp tips, broad tips, brushes, pick equipment, and more.

Hot-air rework stations are also suitable for simple jobs. You can use them for preheating components.

Or reflow components like DIP (Dual Inline Packaging), QFP (Quad flat Packaging) and other ICs. But unlike desoldering stations, hot air rework stations tend to be bulkier.

How to Use a Desoldering Station?

Desoldering stations are great for removing solder to make repairs to components. Most have in-built vacuums to draw the melted solder away and keep the circuit board clean as you work.

To use one, set the temperature required for solder removal on the circuit board. Put solder on the end of the desoldering gun to create a heat bridge.

Hold the heated gun where you want to remove the solder; wait for the solder to melt. Activate the vacuum suction to draw the molten solder away from the board.

Note: Desoldering stations, also known as desoldering guns, are small. This allows you to bring them to any location for removing solder.

Hot Air Rework Station vs Desoldering Station

There are two types of machines for desoldering, and these are:

- Hot Air Rework Stations (Hot air)

- Desoldering Stations (Vacuum)

Hot air rework stations

Hot air rework stations use hot air to melt and remove the solder. These stations are larger and have more features.

Some models include cameras to make seeing smaller parts on circuit boards easier. They also allow for resoldering individual parts.

This makes them ideal for making repairs or changes to individual circuit boards. Most technicians receive training for using hot air rework stations.

However, their larger size and the greater number of features make them more costly. Plus, they require a fixed location with extra circuit boards for the station.

If you often use this device and have a dedicated workshop, a rework station may be beneficial for you.

Desoldering stations (comparison)

In contrast, desoldering stations use a vacuum to heat and suck up the solder attached to the circuit. Most models are much smaller and come in compact designs.

This means you can carry one anywhere you need to use it, unlike the hot air rework station. If you need to work on tiny components, a desoldering station will meet your needs. A great example of this is removing the solder from multiple pass-through parts.

On top of their portability, they are more cost-effective, too. If you are running a small business, such as a repair shop, or have a tiny workbench for the job, opt for this version.

A desoldering station is also the best choice for beginners. For one, it is much more reliable and versatile in nature.

But unlike hot air units, desoldering stations do not permit the soldering of parts. They also do not have numerous features available on some rework stations.

As long as the task does not need these extra features, you will be fine with one.

A Few Factors to Consider

Desoldering stations utilise the principle of vacuum to remove solder. Thus, you must consider the suction power of your chosen desoldering station.

Larger and reliable suction power makes it easier to rely on the desoldering station. This is especially true when dealing with delicate circuitry.

Another key factor to consider is the operational temperature range of the machine. Most entry and basic levels range between 300° and 900° centigrade.

The wider temperature range lets you use the machine for more than just desoldering. This includes other heated removal tasks.

Basic systems provide small temperature adjustments. Meanwhile, more complex systems come with temperature sensors built into the gun tips.

Lastly, given the considerable price range, it is important to have a warranty window. Should any of the parts fail to function due to any defects, you can be confident to have protection.

Most branded machines come with at least one year of manufacturers’ warranty. As always, the higher, the better.

Other Special Tools and Techniques for Desoldering

As mentioned, there are other special tools and techniques to desolder objects. These are:

- Desoldering pumps

- Desoldering guns

- Vacuum pumps with different tips and nozzles

- Desoldering tips and replacements

- Desoldering wicks

Desoldering pumps

Also known as a solder sucker, it works to remove the solder from PCB. It comes in two types: the plunger and the bulb style.

The plunger-style comes with a piston. When triggered by pressing a button, it sucks the solder off the soldered joint.

In contrast, the bulb type sucks the solder by squeezing a rubber bulb in and out.

Desoldering guns

A heat gun is usually used for desoldering SMD (Surface Mount Device) components. In this process, it points toward the desoldering components.

This quickly melts the solder which then lifted with tweezers. Always keep the board flat during the process to avoid any mistakes.

Desoldering wicks

Also known as desoldering braid or solder wick, it is a fine copper braid wire coated with rosin flux.

This copper braid/wick works by melting the solder flux and allowing the copper wick to absorb it. Below, we offer a desoldering wick from the brand Goot.

Desoldering Wick 1.5m

Product code: SI35xx

This braided copper wire Goot desoldering wick removes excess solder from joins. To use, heat the wick slightly and place it across the joint.

Thus, removing any excess solder and neatening up the connection.

Get Your Desoldering Station Here!

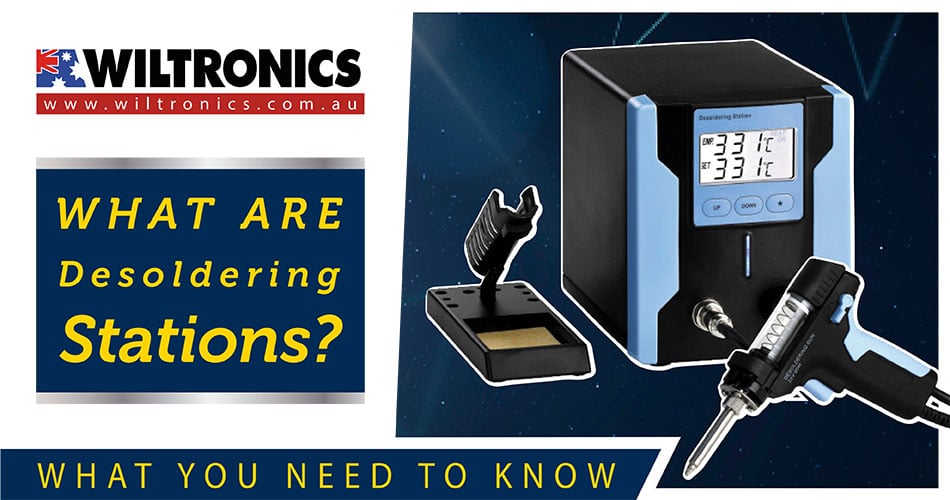

Temp Controlled Vacuum Desolder Station 90W

Product code: ATT2065

A 90W vacuum desoldering station that uses a high-performance ceramic heating element. Even better, a powerful vacuum pump extracts solder from the PCB surface.

The unit has been designed in mind to desolder through-hole componentry efficiently. It is easy to use, making it ideal for both beginners and professionals alike.

Simply place the tip over the solder joint, press the trigger, and the vacuum pump will remove the solder. The removable canister in the handle stores the solder for easy disposal.

The white backlit display indicates the set temperature and heater temperature. It also has an adjustment range between 160°C and 480°C.

Desoldering tips and nozzle cleaners in sizes 1.0, 1.2, and 1.5mm are included. For tip replacements, Round Desoldering Tips (ATT207) are available.

You can buy a variety of soldering and desoldering equipment online from our website. The quality is genuine, and the prices are affordable.

© Electrotech Brands Pty Ltd 2022

Write a Comment

You must be logged in to post a comment.