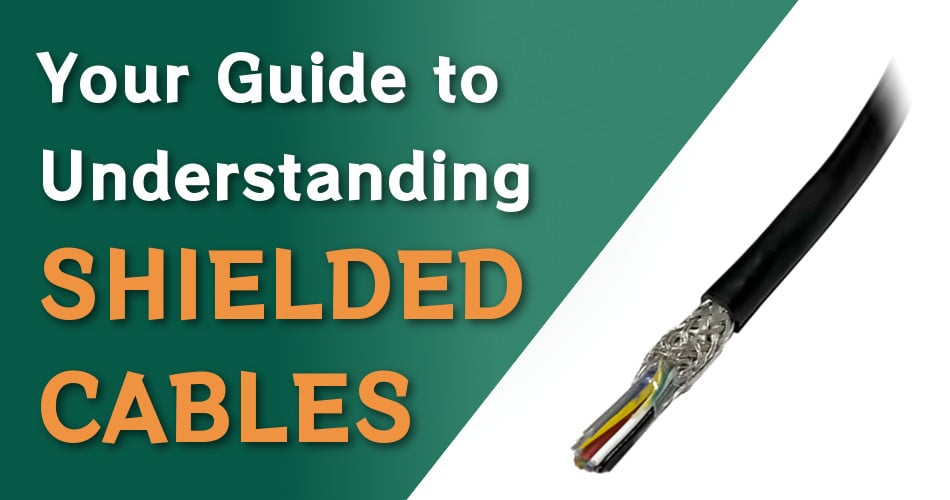

Your Guide to Understanding Shielded Cables

October 13, 2022

The demand for shielding to combat the effects of EMI in industrial applications is on the rise. This is where shielded cables come in.

Although electrical noise is common on factory floors, it should not be overlooked. For one, this interference can disrupt the proper operation of other equipment.

The primary way to stop unwanted noise in cables is through shielding. Shielded cables have various degrees of shielding and effectiveness, depending on several factors.

Thus, it is important to understand how they work and where to apply them best. This guide will introduce shielded cables – with all the basics you need to know.

Understanding Shielded Cables

Electrical cables will radiate energy to, and pick up energy from, their surroundings. Shielding stops that EM energy radiated by a cable, protecting nearby sensitive equipment.

Generally, shielded cables function as electromagnetic energy interceptors. It prevents EMI from travelling to the centre conductor and cutting off the data signal. This means an improved ability to reject noise and handle gigabit Ethernet—all the good stuff!

EMI stands for electromagnetic interference. It is the unwanted noise or interference in an electrical path or circuit due to an outside source.

Besides that, shielding gives protection against damage from cable motion and use. A well-shielded cable can also keep out unwanted external interference.

The structure

Shielding in cable has a conductive layer around its conductors for electromagnetic shielding. It is usually made with foil or braided metal strands.

These strands are often tinned copper, bare copper, aluminium, or other conductive material. But in most cases, you will see them with foil and/or braids, particularly in networking cable.

How Do Shielded Cables Work?

Standard cables can be the main transfer source for EMI, both as a source and receiver. As a source, it can conduct noise to other equipment or act as an antenna radiating noise.

As a receiver, it can pick up EMI radiated from other sources. A shield works on both, surrounding the inner signal- or power-carrying conductors.

Simply put, the shield can act on EMI in two (2) ways: 1.) it reflects the energy, 2.) it picks up the noise and conducts it to the ground.

Shielded vs unshielded cables

Shielded cables are thicker and more rigid than their unshielded counterparts. They also require greater care when working with them.

Shielded cables are most often found in industrial settings. Plus, in installations where nearby equipment is likely to generate electromagnetic interference.

Meanwhile, unshielded ones are for network cabling systems, e.g. in offices. They also do not utilise shielding to reduce interference.

Note: If you are running Cat5e, Cat6 or Cat6A in your home, an unshielded cable will suffice. But if you live close or are running next to power, a shielded cable is your best bet.

Higher-rated categories, such as Cat7A and Cat8, also come with shielding. They are great for achieving high frequencies.

The benefits

Have your cable terminated, bonded and grounded the right way—and you can expect shielding to:

- Decrease the radiated signal from the cable

- Lessen the effects of electrical hazards

- Limit the effect of external EMI on the conductors within the shielded cable

Types of Shielded Cables

There are two common types of shielding used for cables:

- Foil

- Braid

Foil shielding encases a cable using a thin layer of aluminium with a polyester backing. This adds strength and ruggedness, increasing durability.

It offers 100% coverage of the conductors it surrounds. It also works in tandem with a tinned copper drain wire to ground the shield.

But the thinness makes a foil shield trickier to work with, mostly when applying a connector. Usually, the drain wire is used to terminate and ground the shield.

Braid shielding, also known as tinned copper braid, is a woven mesh of bare or tinned copper wires. It is used in conjunction with a metallic shield to ensure effective grounding.

It provides a low-resistance path and serves to complete a circuit from the shield. Then it carries unwanted electrical noise to the ground away from the circuit.

And unlike foil, it is much easier to terminate by soldering when attaching a connector. But it does not provide 100% coverage.

Depending on the tightness of the weave, braids can provide 70% – 90% of coverage. When the cable is stationary, 70% is usually enough.

Note: There is no increase in shielding effectiveness with higher coverage percentage. For one, copper has higher conductivity than aluminium.

The braid also has more bulk for conducting noise, making it more effective as a shield. But it adds size and cost to the cable. For very noisy environments, multiple shielding layers are used—both foil and braid.

In multiconductor cables, individual pairs are shielded with foil. This provides crosstalk protection between the pair. Meanwhile, the overall cable is shielded with foil, braid, or both.

When foil and braid shields are combined, each supports the other. They overcome the limitation of one with its own compensating strengths.

Things to Consider for Effective Shielding

The shielding in cables conducts to ground any noise it has picked up. The cable shielding and its termination must provide a low-impedance path to the ground.

If it is not grounded, again, it will not work as expected. Failure to understand the implications can mean ineffective results.

Consider the following:

- Ensure your cables have enough shielding for the application’s needs. In moderately noisy settings, a foil alone should be adequate. But in noisier environments, consider braids or foil-braid combinations.

- Use a cable suited to the application. Avoid foil-only shielding on flex cables since continuous flexing can tear the foil. Instead, opt for a spirally wrapped shield – for cables experiencing repeated flexing.

- Make sure the equipment where the cable is connected is properly grounded. Use an earth ground wherever possible. Double-check the connection between the ground point and the equipment.

- The connector should offer shielding effectiveness equal to that of the cable. Go for connector designs that allow full 360° termination of the shield.

- Ground the cable at one end to eliminate the potential for noise-inducing ground loops.

When to Choose Shielded Cables?

Suppose you want extra protection from EMI or your cable has higher frequencies. Shielded cables are your best bet. Here are some of the scenarios that can help you decide when to use one:

- When the area is an EM field, including radio transmitters or receivers. Moreover, electrical power lines, radar, engines, electric motors, and broadcasting towers.

- Other than factories, in hospitals and laboratories.

Get Your Shielded Cables Here!

Check out our range of shielded data cables below:

4 Core (2 Pair) Shielded Data Cable 7/0.20

Product code: CB1003-4

This 4-core shielded data cable is two pairs individually shielded with drain wire. Ideal use for computer systems and is available in 100m rolls, 305m rolls and by the metre.

6 Core Shielded Data Cable 7/0.127

Product code: CB1007-8

This 6-core shielded data cable 7/0.127 is sold by the metre and in quantities of 100m. Ideal use for computer systems and 100% screened cable with tinned drain wire.

8-Core Shielded Data Cable 7/0.20

Product Code: CB1010-1

This 8 core shielded data cable is sold by the metre and in quantities of 100m. It’s ideal for computer systems and features a tinned drain wire.

We also have the following variations – all are sold by the metre and in quantities of 100m:

- 2 Core Shielded Data Cable (Product code: CB102x)

- 9-Core Shielded Data Cable 7/0.127 (Product code: CB1013-4)

- 12-Core Shielded Data Cable 7/0.20 (Product code: CB1015-6)

- 25-Core Shielded Data Cable (Product code: CB103x)

The Bottom Line

Shielded cables are great against EMI in networks, particularly in industrial settings. This guide has also broken down the two common types, when to use them, and things to consider.

You should be able to get the right shielded cable for your specific needs!

© Electrotech Brands Pty Ltd 2022

Write a Comment

You must be logged in to post a comment.