What Are Heat Sinks: How They Work, Their Functions and Types

May 10, 2022

Heat sinks are another component you do not want to miss out on when working on electronics.

Have you experienced an overheating CPU? This happens a lot, and multiple factors usually cause it.

For one, too many applications running at once can cause the fans to go into overdrive. Plus, built-up dust can block the fans, causing the CPU to overheat.

Thus, thermal management within a device is crucial, ensuring electronics are reliable. Most thermal management is regulated through a heat sink.

Read on to learn the importance of heat sinks for the thermal management of electronics!

Thermal Management Explained

Heat is an inevitable by-product of electronic devices. Thermal management helps control and dissipate the heat produced by a device.

Overheating can be disadvantageous to the reliability of your device. And thus requires thermal management to improve reliability and prevent premature failure.

Thermal management makes it possible to improve battery power and longevity. And behind this is mostly controlled through a heat sink.

What Are Heat Sinks?

Heat sinks are metal thermal conductors that carry heat away from the CPU. A variety of metals can be used for a heat sink to help an electronic device from overheating. All of which exhibit different thermal conductivity values.

Two of the most commonly used metals for heat sinks are aluminium and copper. Both of which display high thermal conductivity values.

Overall, without heat sinks, modern computers could not run at the speeds they do. Or worse, your computer processor is at risk of overheating. This could destroy your entire system, costing you more money.

Heat sinks can further be classified by their physical designs and the material used, such as:

- Stamped

- Machining

- Bonded-fin

- Folded-fin

- Forged Heat Sinks

- Single Fin Assembly Heat Sinks

- Swaged Heat Sinks

- Skived Heat Sinks

Thermal Conduction

The heat sink operation is based on Fourier’s law of heat. There are three different ways of heat transfer, and that is through:

- Radiation

- Convention

- Conduction

Thermal conduction occurs whenever two objects at different temperatures are in contact. This involves the collisions between the fast molecules vs slow-moving molecules.

Fast molecules are from the hotter object, while the slow ones are from the colder object. This leads to the energy transfer from the hot to the cooler object.

Thus, heat sinks transfer heat from the high-temperature component to the low-temperature medium. This is through conduction and then convection.

Other factors that affect a heat sink’s performance include:

- Thermal Resistance

- Airflow

- Volumetric resistance

- Fin density

- Fin spacing

- Width

- Length

How do heat sinks work?

A heat sink is a component that increases the heat flow away from a hot device. This includes the amount of low-temperature fluids that move across the surface area.

Generally, heat sinks move heat away from a critical component in four basic steps:

1. The source generates heat. This source can come from any system, such as:

- Mechanical

- Electrical

- Chemical

- Nuclear

- Solar

- Friction

They need heat removal to function well.

2. Heat transfers away from the source. The heat moves into the heat sink and away from the source via natural conduction.

This process impacts the heat sink materials’ thermal conductivity. Thus, high thermal conductivity materials like copper and aluminium are ideal.

3. Heat distribution throughout the heat sink. Heat will naturally travel through the heat sink via natural conduction.

It will move across the thermal gradient from a high- to a low-temperature environment. This means that the heat sink’s thermal profile will not be consistent.

As such, heat sinks will often be hotter than the source. Then, cooler towards the sink’s extremities.

4. Heat moves away from the heat sink. This process relies on the heat sink’s temperature gradient and working fluid. Most commonly, air or a non-electrically-conductive liquid.

The working fluid passes across the surface of the warm heat sink. Then it utilises thermal diffusion and convection to remove heat from the surface.

This stage relies on a temperature gradient to remove heat from the heat sink. If the ambient temperature is not cooler than the heat sink, no further heat removal will occur.

In short, heat sinks dissipate excess heat to prevent overheating and premature failure. At the same time, it improves the reliability and performance of the components.

Types of Heat Sinks

There are two types of heat sinks: active heat sinks and passive heat sinks.

1. Active heat sinks

Active heat sinks utilise forced air to increase fluid flow across the hot area. Forced air is usually generated by a fan, blow, or movement of an object.

This type of heat sink basically uses a cooling fan or blower to cool the heat sink. They have excellent cooling performance but need maintenance due to the moving parts.

A great example of a fan producing forced air across a heat sink is when the fan in your PC turns on after your computer gets warm. This allows more unheated air to move across the heat sink surface.

As a result, it increases the total thermal gradient across the heat sink system. This lets more heat exit the overall system.

2. Passive heat sinks

Passive heat sinks rely on convection. This simply means the buoyancy of hot air alone causes the airflow generated across the heat sink system.

They do not use any fans and have no moving parts, and are more reliable. This type of heat sink does not also need secondary power or control systems to remove heat.

But it is less effective at transferring heat from a system than its active counterpart.

3. Hyrbid heat sinks

Now, this type of heat sink combines the aspects of passive and active heat sinks. These configurations are less common and often rely on control systems.

When the system operates at cooler levels, the forced air source is inactive. Thus, the cooling system is passive.

Once the source reaches higher temperatures, the active cooling mechanism engages. This increases the cooling capacity of the heat sink system.

Choosing a Heat Sink

If you are building your own computer, there are factors you need to consider when purchasing a heat sink. For one, the thermal output of the processor you buy should match the thermal handling capability of the heat sink you buy.

To determine the heat sink performance required by the processor, consider the following:

- The maximum allowable case temperature. Consider how hot the actual case of your computer can get without damage.

- The maximum allowable inlet temperature to the heat sink.

- Maximum power dissipation of the processor.

Get Your Heat Sink Supplies Here!

1. HS510 Series Heatsinks

The HS510 series is based on an aluminium extrusion. It is supplied in different lengths in both punched and unpunched versions.

All come with a black anodised finish. Universal punch allows mounting of TO.3, TO.66 and TO.220 packages.

We also have HS410 Series Heatsinks. Universal Punch allows mounting of TO.3, TO.66 and TO.220 Packages.

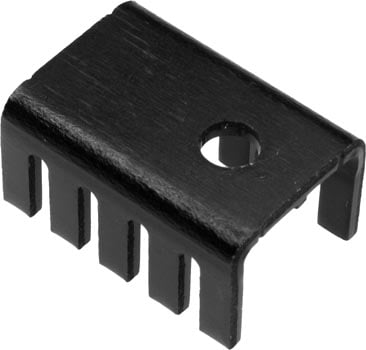

2. Small Heatsinks

These heatsinks are designed to suit TO-126 to TO-220 Transistors, SCR, Triacs, and more:

3. Heatsink Plier

Product code: HT1806

This heatsink plier can be used to remove heat from components when soldering. It is a fantastic tool to have around when electronics work.

4. Heat Transfer Compound

Product code: HT20xx

A heat-conducting paste that facilitates heat transfer from semiconductors to heatsinks. One 10g tube will do up to 30 TO-3 package transistors.

The Bottom Line

Technology products must be reliable. They should be able to perform their required functions under stated conditions.

One way to ensure that an electronic device is reliable is thermal management. This is where heat sinks come into play!

A heat sink is basically a component made of good thermal conducting material. It is attached to an electronic device to dissipate unwanted heat.

In computers, heat sinks are used to cool CPUs, GPUs, some chipsets, and RAM modules. But these are plenty of other devices where these components also come in handy!

© Electrotech Brands Pty Ltd 2022

Write a Comment

You must be logged in to post a comment.